Even though Litilit is not a widely recognised name in Lithuania, it’s actually one of the fastest-growing laser technology companies in the world. The fundamental solution developed and patented by one of Litilit’s co-founders and the Centre for Physical Sciences and Technology improves the efficiency of producing ultra-short pulse lasers 100-fold.

Having attracted the first €1.6 million in seed funding when the company was just a team of 4 specialists, Litilit is now gearing towards expansion. The short-term plan is to have 50 employees, producing 1 laser that costs around €100,000 on a nearly daily basis. The long- term goal is to not only become a unicorn but also to set a new industry standard, making advanced procedures accessible to nearly everyone. The ultra-short pulse laser generator developed by the Lithuanian startup is already being used in the semiconductor and electronics industries, for the processing and manufacture of medical equipment and different materials, during eye surgery, in microscopy, and even for space exploration.

– You’re known in the global laser market, but not in Lithuania – how come? Tell us a little bit about Litilit.

– Litilit stands for Lithuanian Light or Light Light. By using reliable and affordable femtosecond lasers, we’re able to bring progress to industry and medicine alike. We aim to perfect the technology as much as possible, thereby changing the industry as a whole. To make this happen, we have to be 10 times better than our competitors. The most successful startups, however, are precisely those driven by technological breakthroughs, rather than by competitive pricing.

– How does your business model work in practice?

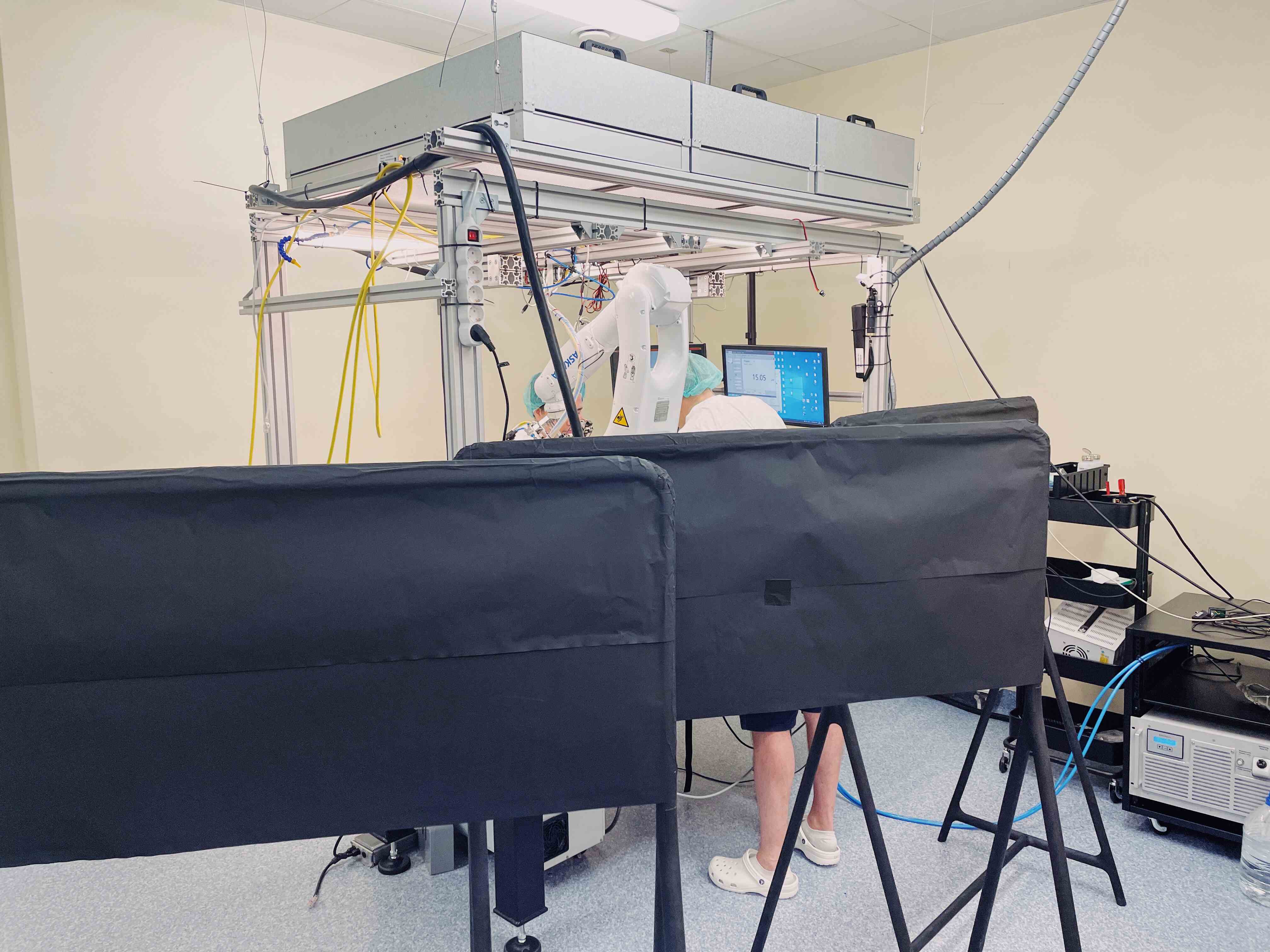

– From the very first research endeavors to the development of advanced prototypes, our company has focused on improving the femtosecond laser technology and, most importantly – on adjusting it to automated serial production. For this purpose, we had to build a highly experienced and competent team, which designed the product from mechanics to software. Since femtosecond lasers have up to now been a niche product, the majority of market participants didn’t see any reason to invest in making them better. It’s also important to note that classic technological solutions essentially put a cap on achievable results even with tons of investment. We decided to forego short-term profit, and the outcome of this approach is now quite obvious. For instance, a typical company produces 1-2 lasers per employee, per year. This means that, to make 1,000 lasers in a year, they need a 500-strong team. Our technology will make it possible to produce the same number of lasers with 50 employees. Since the manufacturing process itself will be automated, employees will have to simply oversee the industrial robots and/or develop new products, which the latter can’t do on their own.

– How do femtosecond lasers actually work? What makes them unique?

– Femtosecond pulses constitute the latest technique used in industrial production, medical treatment, and medical diagnostics. Their duration is less than one-millionth of one-billionth of a second. During this period, light covers the distance of just 100 microns, whereas in a second it can fly around the Earth 7 times. The impossibly short duration of these pulses results in some very interesting and useful interactions with certain materials.

First, during the femtosecond pulse, the light-exposed part of the material evaporates without heating up the surrounding areas, which makes for extreme precision. We call it the “cold process”, and it’s virtually impossible to replicate the effect by any other means. The second feature of femtosecond impulses is their ability to reach a very high optical power during the impulse without damaging the material. For instance, the optical power of an impulse can reach 100 megawatts (comparable to a small electric power plant), while that of a laser is just 10 watts (roughly the same as a light bulb).

The optical power of femtosecond impulses is widely used in non-linear microscopy. For instance, a femtosecond laser can reproduce not just regular, two-dimensional images, but also the sample’s entire three-dimensional structure, which enables the observation of lesions that regular microscopes simply cannot detect. Because of these unique features, the femtosecond technique is now used in diagnosing cancer and other lesions, and for studying brain diseases, including Alzheimer’s. Our femtosecond lasers are currently undergoing clinical trials. If they succeed, we’ll be moving on to applications in clinical settings. Just consider how cancer is diagnosed today. A sample of a suspicious lesion is frozen, sliced using specialised tools (which may by itself lead to changes in fragmentation), and then studied under optical microscopes. Femtosecond lasers make it possible to perform extremely accurate tests within minutes. A patient comes to a doctor who shines a laser on a mole and immediately decides whether to remove it. That’s a real breakthrough.

– Do you already have any functional products, in addition to the prototype?

– Our optical generator emits very high-quality initial light pulses. These can be further expanded or separated, boosted or weakened, yet the pulse doesn’t change due to being genetically correct already during the initial period. The industry didn’t have any such product before. With this discovery, we made 3 laser models within 2 years that have met all the needs of the industry, even though usually the production of femtosecond lasers takes around 10 or more years, and doesn’t always succeed. We knew exactly what product we wanted to make. The technological superiority of the invention also helped.

One of our products – a femtosecond pulse generator – was nominated for the Prism Award. The award given by the world’s largest photonics association in the lasers category is a massive achievement for such a young business. We are competing with billion-dollar companies that have been active in the industry for many decades. And most of them have already tested our pulse generators and are planning to replace their existing solutions with our products.

– You’ve already commercialised the technology that increases the effectiveness of laser production 100-fold. Let me get straight to the point – why were you the ones who succeeded at it?

– Well, how do other ideas that change the world arise in the first place. Humanity needs to first have a problem. Then it has to be developed by forming a critical mass of people who engage in discussions and try hundreds of solutions, until something finally works. We’ve been engaged with this issue from the very beginning. The company was founded by people with different experiences in the same industry. One of our co-founders, Kęstutis Regelskis, decided to tackle it at a fundamental level, creating a completely new method of generating laser beams in the process. It’s basically the same as reinventing the bicycle or the wheel. For two years, we tried to explain and demonstrate to the industry and the scientific community just how important our discovery was. Then we spent another two years making prototypes and mock-ups. And only then did we proceed with investment and commercialisation.

– Tell us a bit more about how Litilit got its start.

– We founded the company 7 years ago, but only got our major investment in 2020. It was €1.6 million from Iron Wolf Capital. Sitting in a tiny office, all four of us worked on the idea. We had a patent that people weren’t terribly confident in. And yet, we managed to more than double the amount invested that same year by making a pitch and securing a €2.5 million research and development subsidy from the EU. Over the past two years, we started collaborating with some of the major companies in our sector, e.g., Coherent, NKT Photonics, Trumpf, IPG Photonics, and others. Our products are now available in Korea, Taiwan, the U.S., and, needless to say – in most European countries. We’re currently negotiating over contracts worth €10-20 million, and our sales potential for the upcoming several years has increased to more €100 million.

– Have you had an interest in business since childhood?

– I’m from Palanga. My dad was a pilot and then a port master. I had a very lively childhood – it was the wild 90s. I was the one who came up with the idea of selling ice cream on the beach. What you see now along the coast was essentially created by me, sitting on a swing, when I was 12 years old. The next day I bought a box of 80 Eskimo ice cream cones for 2,200 vagnorkes (a temporary currency) and sold them all within 5 minutes. At the end of the summer, there were more 20 people working for me. I bought a Zhiguli and a pair of Puma and Nike sneakers. Before finishing school, I started a number of other businesses too.

I don’t know why, but I went to study the mathematics of banking on an overnight train from Kretinga, even though I could’ve afforded a taxi – I had a fairly high income at the time. There I met a couple that mocked my decision and suggested that I should study physics, where things are, supposedly, at least material. I took that advice to heart. For a long time, I didn’t understand anything. Only towards year 4 did it finally dawn on me. Then I did post- graduate studies in Germany. Finally, I joined a company at the lowest rank and went on to become the CTO. I don’t regret it, but it’s very hard to create something completely new in this world.

– Why lasers, specifically?

– At my previous job, we were making laser equipment for telecommunications. It was an older industry, turning out thousands of units, whereas now it’s in the hundreds. I went to study for my PhD where I met Kęstutis. We had an idea, wrote a few successful projects – and the rest is history.

– Is it true that Litilit’s technology is now used even by competitors because there is no better alternative on the market?

– Yes. Today most competitors are using our invention. The feedback is exclusively positive – and we’re not just talking here about some little cog inside a big machine. The pulse generator is a critical component in femtosecond lasers. Respectable companies have very strict requirements when it comes to reliability, stability, and quality. The fact that large enterprises are willing to decommission their long-term, expensive solutions tells you quite a lot about our future prospects.

– It seems as though lasers have become Lithuania’s calling card. How come it’s so advanced in this field?

– Lithuania has 3 strong femtosecond laser manufacturers – and there are only 20 of them in the world. Germany has 6, the U.S. has 4, and countries like Estonia, Latvia, or even Japan have none. It came about historically that Lithuania was always at the vanguard of laser science and technology, which started with Professor Algis Piskarskas, who died just a month ago – he constructed one of the first operational lasers in the world at his lab in Vilnius University. There’s a lot of activity in this sector even now – Lithuania is forming research groups, developing lab infrastructure, and encouraging businesses to invest in various research projects. This long-term strategy has resulted in a critical mass of people – a community – engaged in continuously pushing the boundaries.

Litilit is a product of this community – not unlike the Estonian unicorns that got their impulse from Skype. Having developed the technology, Lithuania now has the right to receive dividends – we’ll employ the talent, pay the taxes, and let the plan bring us advantages both now and in the future. States provide subsidies to laser manufacturers because it’s a strategic industry. Femtosecond lasers are still produced by way of old-style manufactories – like carriages, as compared to sleek, mass-produced cars. During the last several crises it became obvious that moving all production to third countries is short-sighted. Mass- produced femtosecond lasers is a technology that will, in the near future, dictate the progress of high-tech and which, hopefully, will bring photonics back to Europe.

– Your ambitions and goals are quite impressive. What’s missing to make them a reality?

– Time, maturity, and a strong vision. We have a real opportunity in our hands today. By making the right decisions as a country, as a society, we can accelerate that process. We have the technology and the model, but we’re lacking investment and revenue – the focus is currently elsewhere.

We no longer want to experiment – it’s time to reap the rewards and commercialise our ideas. We need to set the parameters and have a scenario that we could sell to others. In 5- 7 years, we’d like to have at least 30 such scenarios, filling up our work portfolio to the hilt. We have a fundamental invention and all the necessary equipment. The process is simple: you show the diagram to an employee, he/she calibrates the equipment, which sometimes only takes about 15 minutes, and kicks off the automated manufacturing process. One week later, the client has a fully functional product. We plan to change the whole market. To increase effectiveness, reduce the price, and become the industry standard. We want to be among the world’s major companies in terms of all relevant indicators and ROI.

– What advice would you give to those dreaming of starting a similar business in the future?

– Once during Christmas, when I was a teenager, I saw a movie depicting the life of very busy businessman. I also wanted to be busy, important, and short on time. That’s how I see people who are successful. And now I’m thinking – why didn’t I want to just be happy? I missed the key part of the movie. Unfortunately, my life has been 6 AM to 12 PM for many years now. I go to see my family in Palanga for 4-8 hours because I can’t afford to stay any longer. It’s just the current stage of my life. I don’t mean to say that I’m unsatisfied, though – it’s my decision, my vision. So I would advise people to first create a comprehensive vision – there’s going to be a lot of work, sacrifices, maybe even self-overcoming. You’ll have to find the right place and the right context, but if you put in a lot of effort – it’ll eventually come.